Manufacturing for Solar

By Kate Bachman | July 12, 2016

Category:

Proactive manufacturers are seeking and finding market opportunities in the solar energy industry. Photo courtesy of Stamp Source, Charlotte, N.C.

Solar energy accounts for 64 percent of new electricity capacity, according to the U.S. Solar Energy Industry Association (SEIA). It is projected to grow an additional 94 percent by the end of this year.

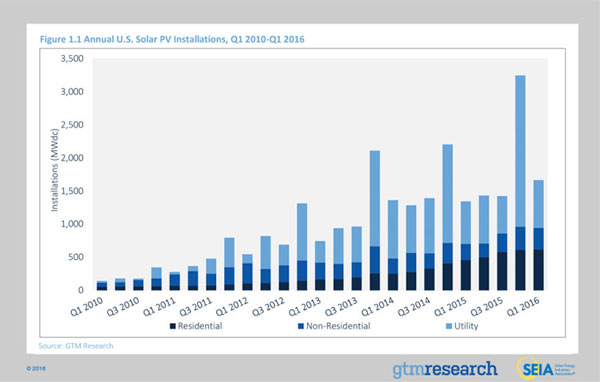

The U.S. installed 1,665 megawatts (MW) of solar PV in the first quarter of 2016 to reach 29.3 gigawatts (GW) of total installed capacity, enough to power 5.7 million American homes (see Figure 1). With more than 1 million individual solar installations nationwide, the industry is on pace to nearly double in size in 2016.

Figure 1: Chart courtesy of the Solar Energy Industry Association

This would lead to conclusions that manufacturing opportunities abound for U.S. manufacturers; however, six of the top 10 solar panel manufacturers are Chinese companies. Trina Solar, Yingli Green Energy, and Chinese-based Canadian Solar are the top three, according to a 2014 FORTUNE® article.

Six manufacturers, including SolarWorld, Johnson Bros. Metal Forming, Hynes Industries, StampSource, All-New Stamping, and CEWA Technologies have found market opportunities in the solar energy industry. Many astute manufacturers have mined opportunities beyond the crystalline silicon modules–and are making coin in the process.

- SolarWorld USA, Hillsboro, Ore., has been the largest manufacturer of solar panels in the U.S since 1975. Brian Lynch, senior sales manager, projects and solutions, SolarWorld Americas Inc., presented at the Sustainable Manufacturer Network conference last year on ways to finance solar array installations.

- Johnson Bros. Metal Forming Co., Berkeley, Ill., roll forms aluminum solar panel frames. In fact, it says they are its specialty (see Figure 2).

Figure 2: Johnson Bros. Metal Forming Co. found its niche in the solar energy industry roll forming solar modules frames.

Founded in 1947, Johnson Bros. has experienced many changes in the industry, along with growth. Annual sales have grown to $7 million with 36 full-time and six part-time employees. Company leadership see market opportunities in renewables. “Outsourcing has made it difficult for American manufacturers and Johnson Bros. in the last few years but the future now looks very promising. As we move into an environmentally friendly society, Johnson Brothers continues to create green energy products,” the manufacturer’s website states.

Because solar panel frames vary greatly in shape, size and weight, the manufacturer makes a range of custom roll-formed shapes for all different solar panel frames and structures. A solar frame must vary in strength based on its intended use and the weight of the panels it will hold. “Solar panel parts and panel components are at the core of what we produce for the solar industry.

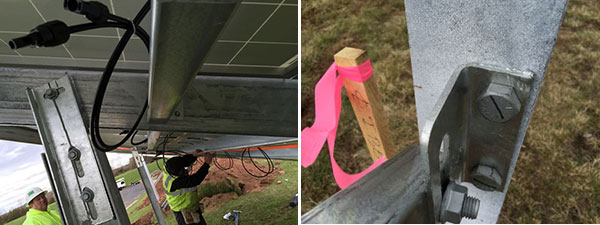

- Hynes Industries, Youngstown, Ohio, manufactures custom roll-formed solar racking components, which are used to hold the solar panels in place on roof installations (see Figure 3). Its foray into the solar industry began as construction and material handling markets were fading. “We were looking for a new, growing market,” remarked Rob Touzalin, innovation and new product development. “We noticed that solar panels had to sit on steel or aluminum structures. We saw that as a new market possibility.”

Figure 3: Roll formed beams, manufactured by Hynes Industries, comprise the bulk of solar panel mounts. Photo courtesy of Hynes Industries.

The company is equipped with 38 automated roll-forming lines with in-line punching and stamping capabilities, and a full complement of secondary finishing equipment.

“A big thing with these mounting systems is the wind load—very important,” Touzalin continued. “These panels have to stay steady at wind speeds from 90 to 120 miles per hour. So we help our customers by suggesting redesigns or by designing stampings that handle the maximal wind load—holding down panels while holding down costs.”

- Stamp Source, Charlotte, N.C., recently boosted its now $13 million annual revenue by entering the solar energy market (see Figure 4).

Figure 4: Stamp Source manufactures the metal structural framework hoisting large solar panels used in solar farms. Photo courtesy of Stamp Source, Charlotte, N.C.

The manufacturer expanded its stamping capacity with three new presses, which empowers it to take on the additional work. Stamp Source makes the structural metal framework underneath the panels that hold them. “One of the things we’re doing on the 275 [new 275-ton press] is work for Daetwyler Clean Energy which makes the framework for solar arrays in solar farms,” said Sharma Burk, sales engineer. One of the OEM’s new projects is building solar farms on top of landfills, she added.

- All-New Stamping has been in stamping and fabricating since 1962 in El Monte, Calif. The manufacturer uses its new Amada fiber laser to blank 0.030-in. aluminum components for large aluminum panel frames. Blanking has traditionally been a stamping process. The panels measure about 1 ft. long by 9 in. wide, with a draw form in the center. “They are for large aluminum panels, part of the framework for roof-mounted solar panels,” said John Ford, sales manager for All-New Stamping. The manufacturer also stamps complex brackets used for the mounts.

- CEWA Technologies has found its solar market opportunity outside of solar photovoltaic modules altogether. The manufacturer makes concentrating solar power (CSP) dishes.

CEWA Technologies is a Wyomissing, Pennsylvania-based developer of concentrating solar power dishes and solar tracking technology to produce sustainable thermal energy and electricity.

The point concentrator dishes tare compact CSP units that use primary and secondary mirrors to efficiently heat a working fluid, generate electricity, or do both at the same time.

The concentrating solar power (CSP) dishes are capable of delivering 33.5 kW of thermal power, 14 kW of electricity or a combination of the two at a price competitive with fossil fuels – even without government subsidies, according to the company.

The company’s website states that CEWA Technologies is actively seeking qualified manufacturers to produce its point concentrator dishes.

Side by side, we move metal fabrication forward.

FMA unites thousands of metal fabrication and manufacturing professionals around a common purpose: to shape the future of our industry, and in turn shape the world.

Learn More About FMA