Bearing Protection for Induction Motors Bears Attention

By Adam Willwerth | January 1, 2013

Category:

A bearing protection ring is available for any NEMA or IEC motor size. It can be factory-installed inside new motors or quickly and easily retrofitted—even in the field—using conductive epoxy (at right).

Inverters, used to control a motor’s speed or torque, can net substantial savings in energy costs, up to 30 percent. Because of this, they have been cited as a key technology to make industrial HVAC systems, automated assembly lines, and other processes more energy-efficient.

But inverters, also known as variable-frequency drives (VFD) and adjustable-speed drives, can induce unwanted motor shaft voltages. Without effective mitigation, these electrical discharges can destroy bearings, causing premature motor failure.

In fact, the costly repair or replacement of failed motor bearings can wipe out any savings that an inverter yields and severely diminish the reliability of an entire motor-driven system. And when an inverter-controlled motor fails, warranty claims against motor and inverter manufacturers may not pan out. Because systems that use inverters are so varied, the liability question is a hot potato.

Many three-phase AC induction motors are available as “inverter-duty” or “inverter-ready” models; however, although these motors have inverter-rated insulation to protect the windings, the bearings—their most vulnerable parts—too often are ignored. For motors without adequate bearing protection, the term “inverter-duty” is misleading because it ignores a major potential cause of premature bearing and motor failure—electrical discharge machining.

How Inverters Cause Motor Failure

Damage to windings and bearings alike is caused by repetitive and extremely rapid pulses applied to the motor from a modern inverter’s nonsinusoidal power-switching circuitry. The names used to describe this phenomenon include harmonic content, parasitic capacitance, capacitive coupling, electrostatic buildup, and common mode voltage.

Regardless of the name used, high peak voltages and fast voltage rise times can cause cumulative degradation of insulation, bearings, coil varnish, and so forth. If the load impedance is higher than the line impedance, current is reflected back toward the inverter, creating voltage spikes at the motor terminal that can be twice as high as the DC bus voltage.

The cumulative bearing damage caused by inverter-induced currents is often overlooked until it is too late to save the motor.

Types of Bearing Damage

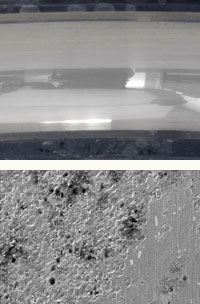

Figure 1, 2Viewed under a scanning electron microscope, a new bearing race wall is a relatively smooth surface, marked by nothing but mechanical wear where bearings contact the wall (left) A bearing race wall can become pitted by frequent discharges (right).

Without some form of mitigation, shaft currents discharge through bearings, causing unwanted electrical discharge machining that erodes the bearings and race walls (see Figure 1) and leads to premature bearing/motor failure. Before long these frequent discharges can leave the entire bearing race riddled with pits known as frosting (see Figure 2).

In fact, electrical damage has become the most common cause of bearing failure in inverter-controlled AC motors.

In a phenomenon called bearing fluting (see Figure 3), the operational frequency of the inverter causes concentrated pitting at regular intervals along the race wall, forming washboard-like ridges. Fluting can cause excessive noise and vibration, which, in an HVAC system, can be magnified and transmitted by ductwork throughout the entire building. By the time this is noticeable, bearing failure is often imminent.

Clearly, protecting motor bearings from catastrophic failure is critical to maintaining the sustainability of inverter-controlled motor systems.

Mitigating Bearing Damage With Motor Shaft Grounding Rings

A reliable and cost-effective way to minimize electrical bearing damage and make motor-driven systems with inverters sustainable is a motor shaft grounding ring. In motors greater than 100 HP, the grounding rings should be combined with insulation. An inverter-ready motor should be designed so that the motor’s bearings are protected as well as its windings.

The following measures have proven effective under actual operating conditions:

- For motors up to 100 HP, in which common mode voltages could cause bearing damage, adding a shaft grounding ring to the motor, either inside the motor or externally, provides effective protection against bearing currents for motor bearings as well as attached equipment (see Figure 4).

- For motors more powerful than 100 HP, in which both circulating currents and common mode voltages could cause bearing damage, combining an insulated bearing on one end with a shaft grounding ring on the opposite end provides protection from electrical bearing damage (see Figure 5).

Other devices that are designed to provide a path to ground, such as metal spring-pressure grounding brushes and carbon-block (graphite) brushes, rely on direct contact to transfer current.

One type of motor shaft grounding ring works both with contact and also without direct fiber contacting the motor shaft. It discharges shaft voltages even if its fibers are not touching the motor shaft, rendering it an effective device for redirecting currents from shaft to ground (see Figure 6).

By preventing electrical damage to bearings, the ring protects the whole inverter system from costly downtime and unplanned maintenance.

Advances in Bearing Grounding Technology

Figure 6

As shown by an oscilloscope, motor shaft currents are more damaging before (top) installation of a bearing protection ring (bottom) on a motor in an HVAC unit.

New grounding rings encircle a motor’s shaft with contact points to enhance effectiveness. One ring type has continuous circumferential rows of specially engineered microfibers to boost electron transfer rates and provide very low impedance from shaft to frame.

These rings are designed to safely bleed damaging currents to ground, bypassing a motor’s bearings entirely. And because the microfiber brushes work with little or no contact, they resist wear.

Most motors—including HVAC motors that run fans in air handlers, defusers, and diverters; pumps such as chill water pumps, condensers, and variable-flow refrigerant pumps; conveyor motors for materials handling; and general-purpose and brake motors for machinery in many manufacturing applications—can be equipped with bearing protection rings as a standard or optional feature.

Stronger Standards, Motor Failure Mitigation

The National Electrical Manufacturers Association (NEMA) Standard MG1-2009 (Revision 1-2010), Section IV, Part 31, Definite-Purpose Inverter-Fed Polyphase Motors, states: “Shaft voltages can result in the flow of destructive currents through motor bearings, manifesting themselves through pitting of the bearings, scoring of the shaft, and eventual bearing failure.”

NEMA points out that “insulating the motor bearings will not prevent the damage of other shaft connected equipment.” When insulation simply blocks the path to the bearings, the damaging current seeks another path to ground. That other path can go through a pump, gearbox, tachometer, encoder, and so forth, which consequently can end up with bearing damage of its own.

Although current NEMA standards highlight the possible need for extra bearing protection for inverter motors, the language may not be specific enough. Stronger, reworked standards calling for effective mitigation in the form of reliable, long-term shaft grounding technology could go a long way toward motor failure mitigation.

National Electrical Manufacturers Association (NEMA), www.nema.org.

Side by side, we move metal fabrication forward.

FMA unites thousands of metal fabrication and manufacturing professionals around a common purpose: to shape the future of our industry, and in turn shape the world.

Learn More About FMA