Optimize Safeguarding at Your Facility

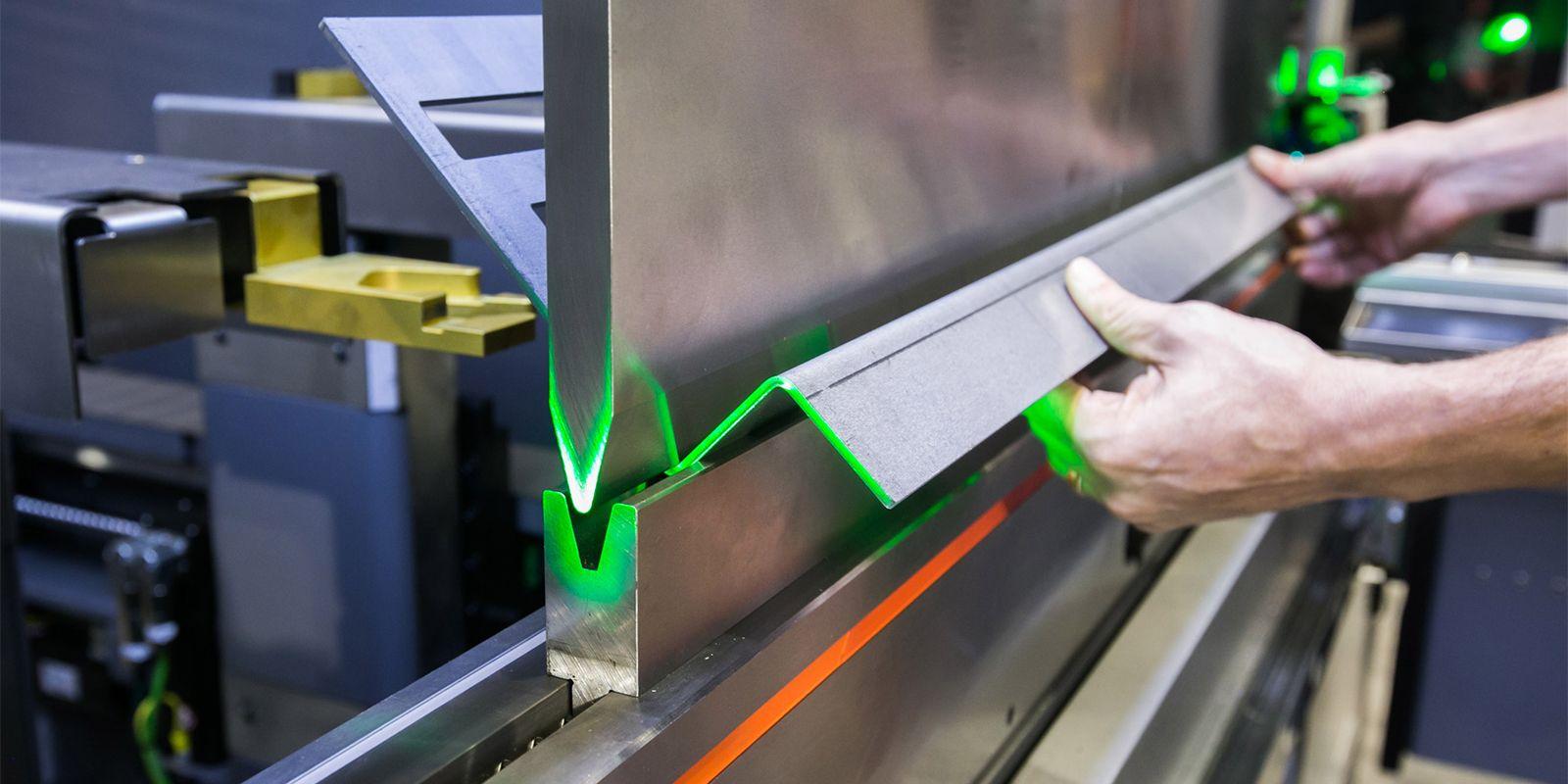

By their nature, press brakes can require close operator proximity to many tons of force. Therefore, these unforgiving machines make it crucial to know best practices for safeguarding them.

At this one-day seminar taught by an industry expert, lessons are based on real-world shop applications to better understand machine safeguarding standards, industry safety requirements, and application-specific safeguarding system selection. You’ll hear case studies of optimally safeguarded systems and learn about current technologies that maximize compliance, safety, and productivity.

Course Availability

On-Site Press Brake Safeguarding Training

Unable to send your operators to off-site training? Bring the instructor and course to you. Schedule expert training in your plant, on your equipment. We also provide assessment testing so your operators can earn a technical certificate after completing their training.

Learn MoreThis Course is Designed For

- All levels of press brake operators or supervisors

- Owners, operators, managers, and safety personnel

- Anyone responsible for safety measures at their facility

This course may qualify toward up to seven hours of professional development or recertification credits. It is the attendee's responsibility to verify qualifications and applicability with their organization or credentialing body.

Testimonial

"Come get this training! The instructor was knowledgeable, prepared, and covered lots of material. I learned a great deal in a short amount of time."

Standards and Regulations

- The history of Occupational Safety and Health Administration (OHSA)

- National and state-level OSHA

- The history of American National Standards Institute (ANSI)

- Identifying how OSHA and ANSI are related

Risk Assessment

- OSHA Job Hazard Analysis

- Objectives of ANSI B11.0 and B11.TR3

- Apply learned concepts to case studies and actual practice in the field

B11.3 Overview

- Standard organization and effective dates

- Scope and definitions

- General requirements

- Control reliability

Press Brake Operation, Application, and Uses

- Machine types and uses

- Tooling variants

Individual Responsibilities

- Supplier responsibilities

- Design and construction

- Specific requirements for mechanical brakes (including servo-driven brakes)

- Specific requirements for hydraulic brakes

- Specific requirements for pneumatic brakes

- Modifier responsibilities

- Reconstruction and modification

- Personnel responsibilities

- User responsibilities

Installation, Setup, and Maintenance

- Layout, installation, testing, and startup

- Setup requirements

- Written user plan

- Maintenance

- Maintenance procedures

- Lockout/tagout

- Setup and operation requirements

- Die setup and operation (written SOP)

- Backgauge operations

- Standard operating procedures

- Supervision

Training and Control Reliability

- Control reliability

- Safeguarding of the rear of the machine

- Safeguarding the backgauge

- General elements and guidelines for training

- Maintenance training

Definitions of Press Brake Safeguarding

- Risk assessment

- Correct holding of material

- ¼" stroke safeguarding

- Safe distance safeguarding

- Safe speed safeguarding

- Engineered methods — safety devices

Applications of Press Brake Safeguarding

- ¼" stroke safeguarding

- Safe distance safeguarding

- Safe speed safeguarding

- Pullbacks and restraints

- Two-hand control devices

- Light curtains (presence sensing devices) for mechanical brakes

- Light curtains for hydraulic brakes

- Close proximity point of operation (AOPD) safeguarding (laser devices)

Appropriate Usage

- Machine considerations

- Operator considerations

- Compliance considerations

- Identify best practices in case studies

*The Press Brake Safeguarding Certificate does not imply the designation of a professional certification, nor does it require renewal.