How Energy-from-Waste Works

By Derek W. Veenhof | December 12, 2012

Category:

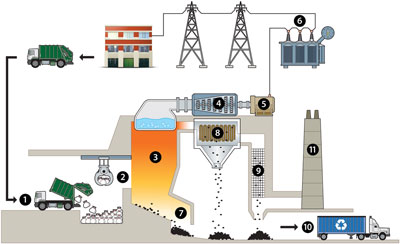

Energy can be recovered via energy-from-waste (EfW) processes from residual waste left over after efforts to reduce, reuse, and recycle have been exhausted. The process is simple: Solid and liquid waste is transferred to a combustion chamber; the heat from the process boils water, which makes steam which drives a turbine that generates electricity.

1. Solid and liquid waste is delivered to an EfW facility and stored for processing.

2. The waste is transferred to a combustion chamber where self-sustaining combustion is maintained at extremely high temperatures. The facility maintains the building around the tipping and bunker area under negative pressure and uses this air in the combustion process to control odor.

3. The heat from the combustion process boils water.

4. & 5. The steam from the boiling water is used directly or drives a turbine that generates electricity.

6. Electricity is distributed to the local grid.

7. & 8. Ash from combustion remnants is processed to extract metal, which is then recycled. The remaining ash is then combined with residue from the air pollution control process (see steps 9 and 10).

9. All gases from the combustion process are collected, filtered, and cleaned with current air pollution control technology that operates to state and federal standards before being emitted into the atmosphere.

10. The combined residue is either beneficially reused or disposed of in a landfill.

11. Emissions and other operating criteria are closely monitored to ensure compliance with permit conditions.

Side by side, we move metal fabrication forward.

FMA unites thousands of metal fabrication and manufacturing professionals around a common purpose: to shape the future of our industry, and in turn shape the world.

Learn More About FMA